In the ever-evolving oil and gas industry, precision and reliability are non-negotiable. Equipment failures can lead to significant financial losses, operational downtime, and safety hazards. Precision-machined components help promote efficiency, reliability, and safety across oil and gas operations.

At WIPCO, we understand the high stakes and offer unparalleled precision machining solutions tailored to the industry’s stringent requirements.

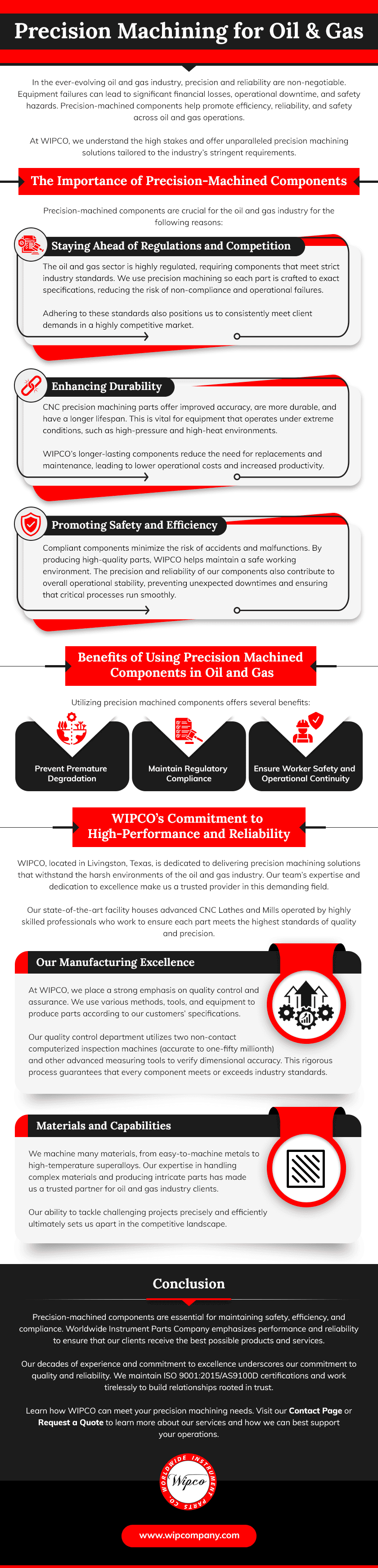

The Importance of Precision-Machined Components

Precision-machined components are crucial for the oil and gas industry for the following reasons:

Staying Ahead of Regulations and Competition

The oil and gas sector is highly regulated, requiring components that meet strict industry standards. We use precision machining so each part is crafted to exact specifications, reducing the risk of non-compliance and operational failures.

Adhering to these standards also positions us to consistently meet client demands in a highly competitive market.

Enhancing Durability

CNC precision machining parts offer improved accuracy, are more durable, and have a longer lifespan. This is vital for equipment that operates under extreme conditions, such as high-pressure and high-heat environments.

WIPCO’s longer-lasting components reduce the need for replacements and maintenance, leading to lower operational costs and increased productivity.

Promoting Safety and Efficiency

Compliant components minimize the risk of accidents and malfunctions. By producing high-quality parts, WIPCO helps maintain a safe working environment. The precision and reliability of our components also contribute to overall operational stability, preventing unexpected downtimes and ensuring that critical processes run smoothly.

Benefits of Using Precision Machined Components in Oil and Gas

Utilizing precision machined components offers several benefits:

- Prevent Premature Degradation. Components in the oil and gas industry endure significant stress. Precision machining eliminates minor inaccuracies leading to premature wear and tear, ensuring components last as intended. This also reduces maintenance costs, leading to long-term savings and improved operational efficiency.

- Maintain Regulatory Compliance. Precision-machined components meet these stringent requirements, helping avoid fines and operational disruptions. Adhering to these regulations also enhances the credibility and reputation of your company, ensuring trust and reliability in your operations.

- Ensure Worker Safety and Operational Continuity. Defective components can cause equipment failures, posing safety risks and leading to shutdowns. High-quality precision machining ensures all parts function correctly, protecting workers and maintaining continuous operations. Investing in precision machined components also reduces costly downtimes and enhances overall productivity.

WIPCO’s Commitment to High-Performance and Reliability

WIPCO, located in Livingston, Texas, is dedicated to delivering precision machining solutions that withstand the harsh environments of the oil and gas industry. Our team’s expertise and dedication to excellence make us a trusted provider in this demanding field.

Our state-of-the-art facility houses advanced CNC Lathes and Mills operated by highly skilled professionals who work to ensure each part meets the highest standards of quality and precision.

Our Manufacturing Excellence

At WIPCO, we place a strong emphasis on quality control and assurance. We use various methods, tools, and equipment to produce parts according to our customers’ specifications.

Our quality control department utilizes two non-contact computerized inspection machines (accurate to one-fifty millionth) and other advanced measuring tools to verify dimensional accuracy. This rigorous process guarantees that every component meets or exceeds industry standards.

Materials and Capabilities

We machine many materials, from easy-to-machine metals to high-temperature superalloys. Our expertise in handling complex materials and producing intricate parts has made us a trusted partner for oil and gas industry clients.

Our ability to tackle challenging projects precisely and efficiently ultimately sets us apart in the competitive landscape.

Conclusion

Precision-machined components are essential for maintaining safety, efficiency, and compliance. Worldwide Instrument Parts Company emphasizes performance and reliability to ensure that our clients receive the best possible products and services.

Our decades of experience and commitment to excellence underscores our commitment to quality and reliability. We maintain ISO 9001:2015/AS9100D certifications and work tirelessly to build relationships rooted in trust.

Learn how WIPCO can meet your precision machining needs. Visit our Contact Page or Request a Quote to learn more about our services and how we can best support your operations.