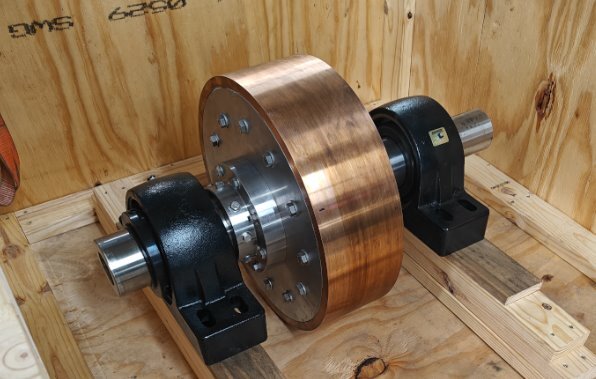

Case Study: Precision Machining for NASA’s Melt Spinner Caster Wheel Assembly

Client Overview: NASA

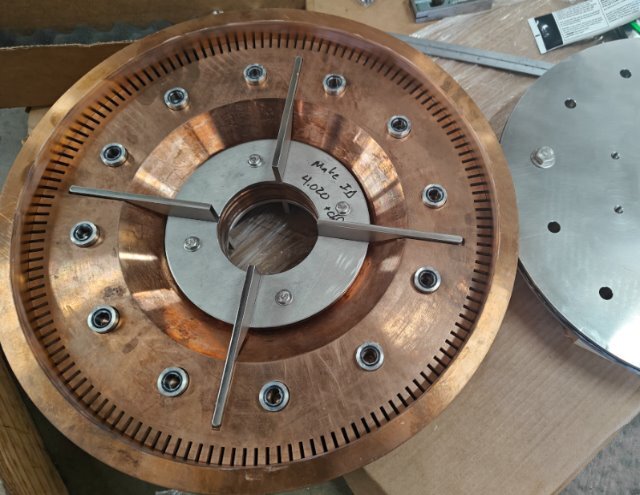

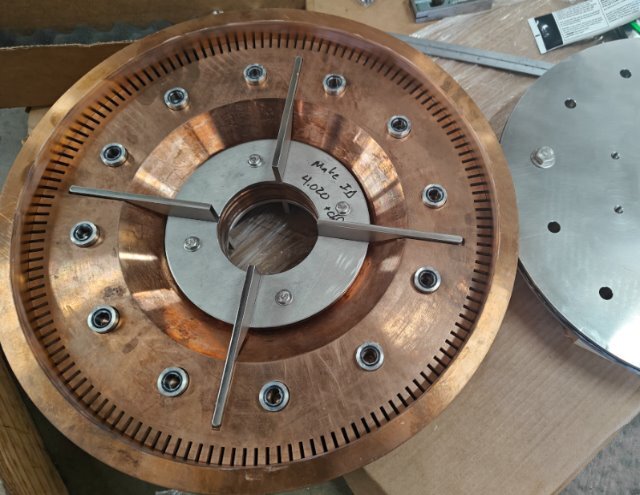

NASA’s Cleveland facility required a replacement for a worn-out Melt Spinner Caster Wheel Assembly, a critical component in their operations. Due to the assembly’s complexity and the use of beryllium copper—one of the most challenging materials to machine—NASA faced significant difficulty in finding a qualified manufacturer. Previous vendors had struggled with the material or were unwilling to take on the project due to its complexity.

Challenge

NASA needed a machining partner capable of:

- Working with beryllium copper and other superalloys.

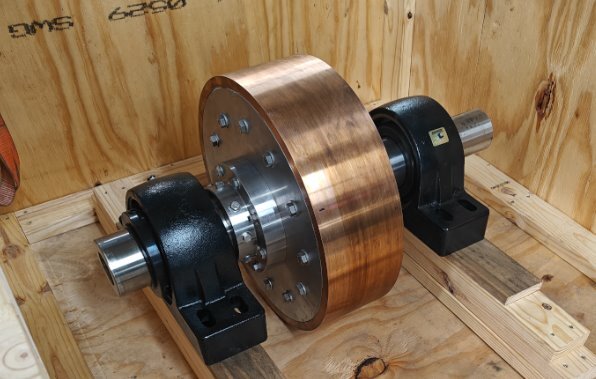

- Producing a large, intricate assembly consisting of approximately ten machined components and multiple buyout items.

- Delivering a fully assembled, tested, and certified product within strict quality and timeline requirements.

- Overcoming issues with previous vendors who either declined the project or failed to meet NASA’s specifications.

- Finding a shop with the expertise to machine exotic metals and handle complete assembly—an obstacle many manufacturers couldn’t overcome.

Solution: WIPCO’s Expertise in Exotic Metals and Assembly

Initially tasked with machining a beryllium copper component, WIPCO quickly demonstrated our capabilities, leading NASA to inquire whether we could handle the entire assembly.

Key aspects of WIPCO’s approach:

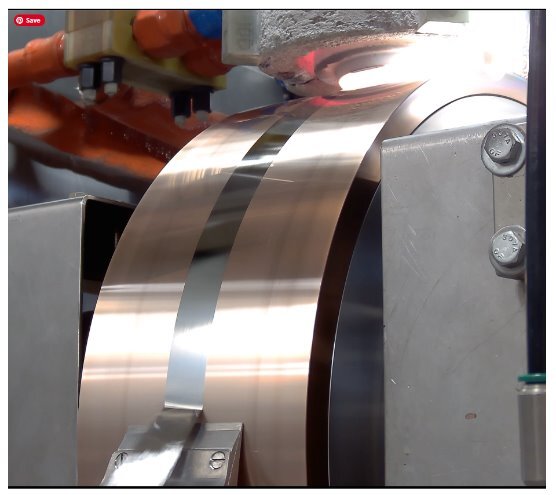

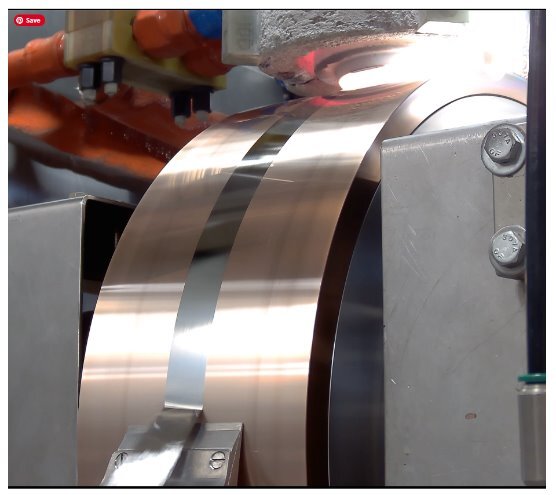

- Material expertise: WIPCO specializes in machining superalloys, including beryllium copper, which requires accurate and specialized handling due to its unique properties.

- End-to-end assembly: WIPCO managed the entire assembly process in-house, utilizing a dedicated assembly area for precision and efficiency. Our Shop Manager and Johnnie , ensured each component fit seamlessly.

- Sourcing high-performance components: Many buyout components, such as O-rings, bolts, and washers, required careful handling and integration to meet NASA’s stringent performance standards.

- Collaborative development: WIPCO maintained continuous communication with NASA engineers, identifying and resolving design revisions to ensure a smooth process from start to finish.

- Quality assurance and testing: The final assembly underwent rigorous pressure testing and quality control inspections, with documented results included in the certification package provided to NASA.

Results

- Successful delivery: The completed Melt Spinner Caster Wheel Assembly was delivered on time and met all specifications outlined by NASA.

- Precision and performance: WIPCO’s meticulous attention to detail ensured flawless operation and vibration-free balance.

- Streamlined production: By optimizing certain design elements, WIPCO helped improve production time and reduced potential manufacturing inefficiencies.

Client Feedback

NASA engineers appreciated WIPCO’s proactive communication, precision machining, and ability to handle intricate assemblies. Their testimonial highlighted WIPCO’s dedication to quality, problem-solving, and collaboration.

Confidentiality and Future Opportunities

The successful completion of the Melt Spinner Caster Wheel Assembly has strengthened WIPCO’s relationship with NASA, positioning us as a trusted partner for future aerospace projects. With decades of experience and ISO 9001:2015/AS9100D certification, WIPCO has proven its ability to meet the complex demands of the aerospace and defense industries.

As NASA continues to explore innovative solutions, WIPCO is ready to support upcoming projects with the same dedication to quality and performance that defined this collaboration.

If you’re seeking a reliable partner for your next precision machining or assembly challenge, contact us today to discuss how WIPCO can help turn your vision into reality.