Inconel is a family of superalloys meant for some of the toughest applications in manufacturing. This nickel alloy is extremely resistant to corrosion, oxidation, and scaling when subjected to high-temperature environments. Inconel can even withstand temperatures that would make plain steel lose tensile strength.

The alloy can also withstand dramatic pressure changes. Its temperature and pressure tolerance make Inconel the perfect material for use in extreme operating environments, such as nuclear power plant reactors, rocket engine thrust chambers, marine equipment, and firearm sound suppressor baffles.

Read on to learn more about the types and applications of Inconel. You’ll also learn about the machining services we offer at Worldwide Instrument Parts Company (WIPCO).

Inconel Machining Services

Based in Livingston, Texas, WIPCO provides precision machining for Inconel parts. Our experienced team uses state-of-the-art machines such as CNC mills and lathes to machine your parts. We regularly machine the most common grades of Inconel: 925, 725, 718, and 625.

In addition to machining Inconel, WIPCO offers value-added services such as coating, grinding, third-party inspection, heat treating, bead blasting, and more. Our full suite of capabilities ensures customers get a turnkey solution. WIPCO is classified under the following NAICS codes:

- 336412: Aircraft Engine and Engine Parts Manufacturing

- 332710: Machine Shops

We are also certified under ISO 9001:2015 and AS9100D.

Types of Inconel

Types of Inconel

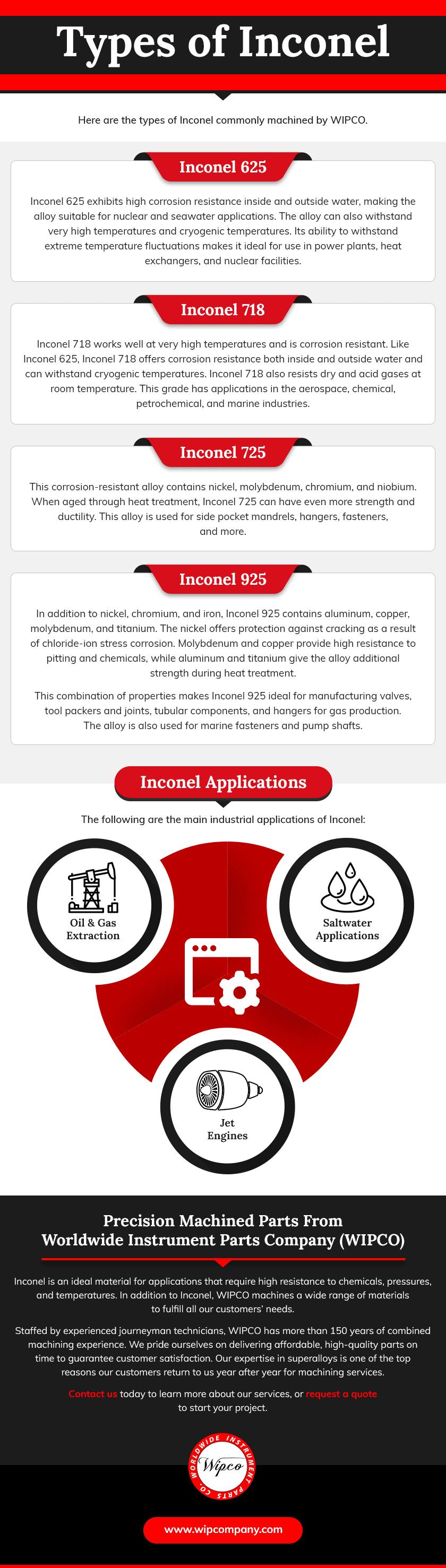

Here are the types of Inconel commonly machined by WIPCO.

Inconel 625

Inconel 625 exhibits high corrosion resistance inside and outside water, making the alloy suitable for nuclear and seawater applications. The alloy can also withstand very high temperatures and cryogenic temperatures. Its ability to withstand extreme temperature fluctuations makes it ideal for use in power plants, heat exchangers, and nuclear facilities.

Inconel 718

Inconel 718 works well at very high temperatures and is corrosion resistant. Like Inconel 625, Inconel 718 offers corrosion resistance both inside and outside water and can withstand cryogenic temperatures. Inconel 718 also resists dry and acid gases at room temperature. This grade has applications in the aerospace, chemical, petrochemical, and marine industries.

Inconel 725

This corrosion-resistant alloy contains nickel, molybdenum, chromium, and niobium. When aged through heat treatment, Inconel 725 can have even more strength and ductility. This alloy is used for side pocket mandrels, hangers, fasteners, and more.

Inconel 925

In addition to nickel, chromium, and iron, Inconel 925 contains aluminum, copper, molybdenum, and titanium. The nickel offers protection against cracking as a result of chloride-ion stress corrosion. Molybdenum and copper provide high resistance to pitting and chemicals, while aluminum and titanium give the alloy additional strength during heat treatment.

This combination of properties makes Inconel 925 ideal for manufacturing valves, tool packers and joints, tubular components, and hangers for gas production. The alloy is also used for marine fasteners and pump shafts.

Inconel Applications

The following are the main industrial applications of Inconel:

- Oil and gas extraction: Inconel is widely used in oil and gas extraction because of its oxidation and temperature resistance properties. Specifically, Inconel 625 is effective at separating fluids in processing systems for liquefied natural gas production.

- Saltwater applications: Owing to its high sodium chloride resistance at different temperature ranges, Inconel is often used in marine applications and power plants that use seawater coolants.

- Jet engines: Due to its ability to withstand extremely high and low temperatures, Inconel is used to construct jet engines and turbines.

Precision Machined Parts From Worldwide Instrument Parts Company (WIPCO)

Inconel is an ideal material for applications that require high resistance to chemicals, pressures, and temperatures. In addition to Inconel, WIPCO machines a wide range of materials to fulfill all our customers’ needs.

Staffed by experienced journeyman technicians, WIPCO has more than 150 years of combined machining experience. We pride ourselves on delivering affordable, high-quality parts on time to guarantee customer satisfaction. Our expertise in superalloys is one of the top reasons our customers return to us year after year for machining services.

Contact us today to learn more about our services, or request a quote to start your project.